Setup tutorial: New Nautilus Evo in Bolzano

14 November 2024

New Nautilus Evo is made from lightweight recycled plastic, allowing for fast and easy setup.

Watch our video to see how New Nautilus Evo was set up in Bolzano, Italy, reducing construction costs and CO2 emissions.

Designed for efficient manual setup, New Nautilus Evo enables the construction of lightened slabs using up to 30% less concrete. This reduces both material costs and environmental impact, contributing to a more sustainable and cost-effective building process.

At the Bolzano site in Italy, our clients used New Nautilus Evo half-modules to create lightened slabs in just a few simple steps:

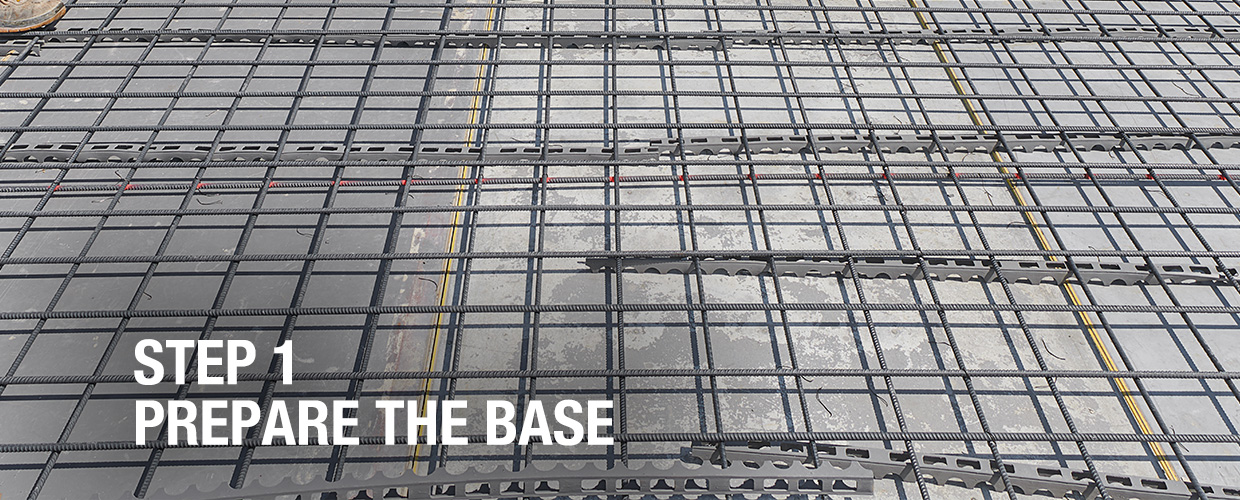

Prepare the base

The lower reinforcement rebar was installed on the level concrete deck, providing the necessary support for the slab.

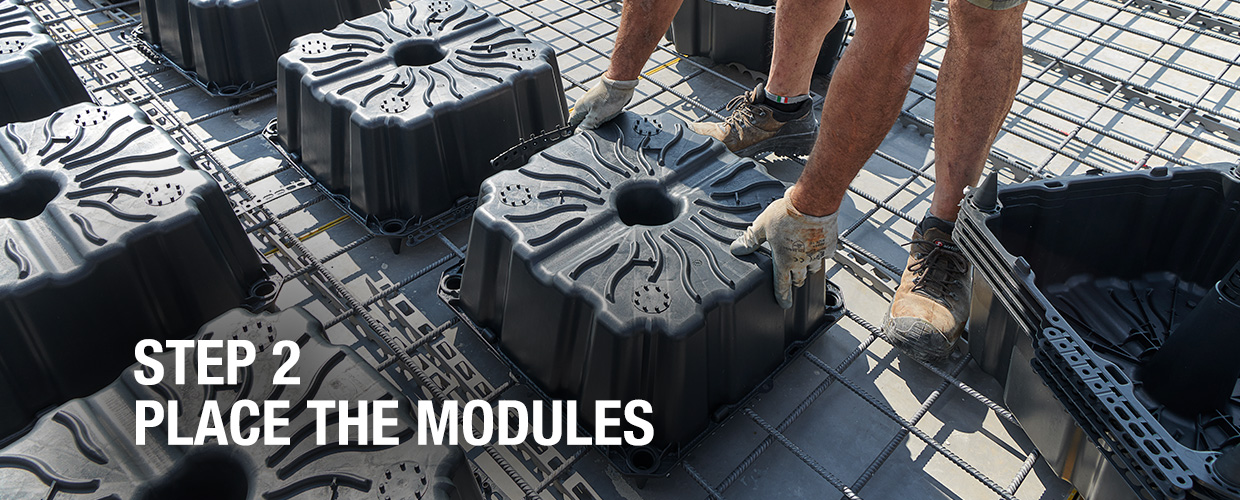

Place the modules

Next, New Nautilus Evo half-modules were placed on the prepared concrete base.

Connect the modules

The modules were connected using specifically designed metal accessories for proper spacing and alignment.

Add upper rebar

Upper reinforcement rebar was added according to project specifications.

Pour the concrete

Concrete was poured in two stages: first, halfway up the modules with vibration to remove air pockets, then a second pour to complete the slab.

Watch our installation video to see how easily New Nautilus Evo was set up on-site.

To purchase or learn more about New Nautilus Evo, contact Federico Minaldo, our Chief Engineering Officer, at federico.minaldo@geoplastglobal.com or connect with him on Linkedin.