New Elevetor is over 12 times less expensive to transport than EPS or gravel

24 March 2021

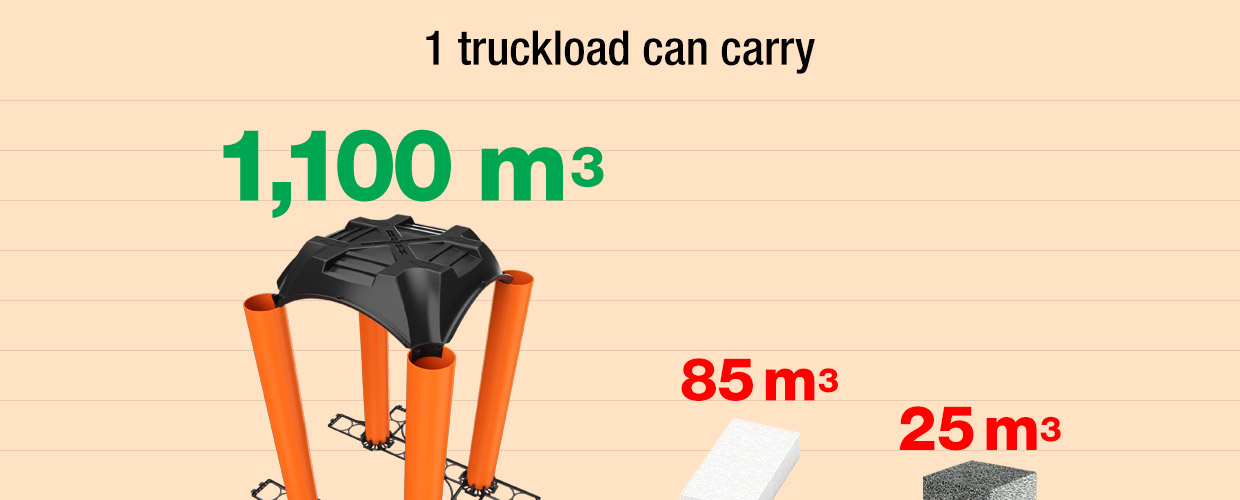

New Elevetor is made of lightweight recyclable plastic elements that fit perfectly together. This makes it exceedingly more compact than traditional backfilling materials like expanded polystyrene (EPS), gravel, or soil. In comparison:

1 truckload can carry:

|

New Elevetor 1,100m3 |

EPS 85m3 |

Gravel or backfill soil 20-25m3 |

New Elevetor

1,100m3

EPS

85m3

Gravel or backfill soil

20-25m3

Because of New Elevetor’s high stackability and lightness, the volume of material that needs to be transported is reduced 12 to 44 times, which significantly lowers the transport and handling costs. Compared to traditional solutions, it also offers many other advantages:

- Requires less storage space on the construction site,

- No cranes or heavy machinery are needed for installation,

- Accelerates the building process,

- Merges 3 stages of concrete pouring: foundation beams, backfilling, and casting of slabs,

- Creates inspectable crawl spaces, suitable for MEP and vapor mitigation,

- It is modular, height-adjustable, and can be used for access ramps, stairs, or different leveled surfaces,

- Due to its high load-bearing capacity, it is suitable for foundations, urban landscaping, and heavy-duty paved surfaces,

- It is made of recycled materials and more sustainable than other solutions.

Learn more about New Elevetor

New Elevetor documentation

New Elevetor research papers

New Elevetor projects

EXPO 2020 Dubai Thematic District, UAE

Refrigeration warehouse, Padua, Italy

Municipal swimming pool renovation, Bazas, France

Symbiosis Business District’s main square, Milan, Italy