Solving concrete is not that simple! a reply to CNN

by Nikola Tosic, 10 May 2018

On 4th May 2018 CNN published an article Can the building industry break its addiction to concrete? The article simplifies concrete problems and presents some solutions. It is a very good that the general audience is introduced to the problems of concrete but we think that article could have said more.

Geoplast is a company dedicated to concrete for past 4 decades. Many of our products and solutions are dedicated to managing and shaping the concrete. Our experience has thought us that solving concrete is not that simple! Concrete damages the environment and our other resources in many ways, but simply substituting it is not enough. Our approach is smart: reduce the use of concrete while building performance is improved. Construction industry will not switch off concrete any time soon, but it can be motivated to use less of it especially if it results in cheaper and safer building processes, and more sustainable, safer, and healthier buildings.

Here are the main points how our products and solutions improve the global impact of concrete:

1. Use less concrete

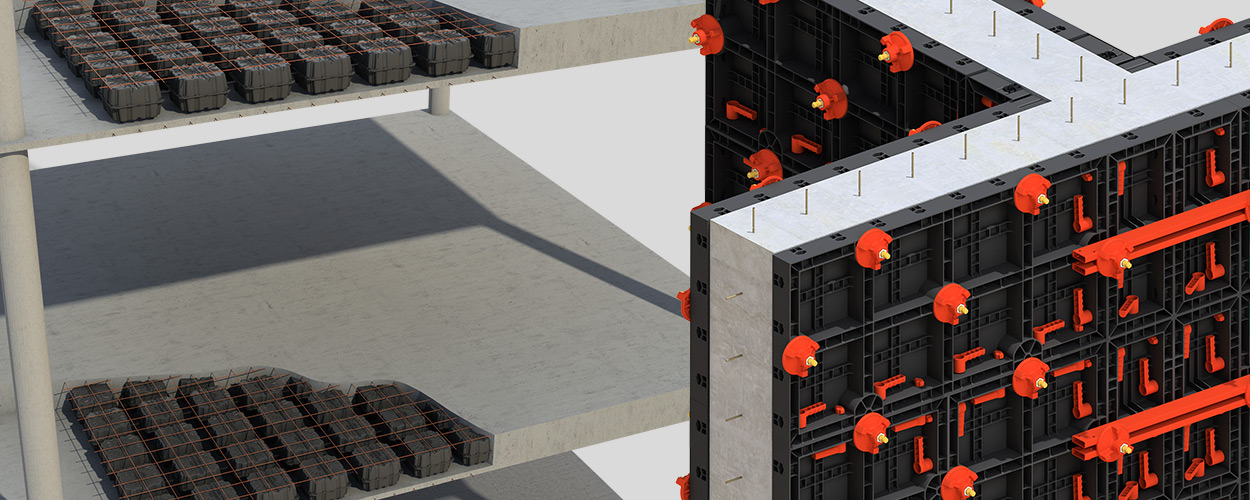

Less concrete can be used if our Foundation and Slab solutions are applied. Our solutions are based on the concept that concrete maintains its strength even if the whole space is not filled, but only specific parts of the space are filled. These parts are filled with the use of our recycled plastic molds. See Francesco’s article: How much is 30 liters of concrete?

2. Less logistics

Less concrete requires less logistics which not only decreases the use of energy in transportation, but overall use of resources in building. If you need 20 % less concrete to finish a project, this also means a lot of other resources will be reduced as well. See our Build Fast Method.

3. Better earthquake resistance

Earthquake resistance is improved with the use of our Foundation and Slab solutions again due to reduced overall weight of the building. So the building does not retains the strength with less concrete, but it actually becomes more resistant to earthquakes. See our comparison between full and voided slabs.

4. Formworks improvement

Building with and repair of concrete is drastically improved with our recycled plastic formworks which are reusable. One of the biggest damages caused by concrete are the formworks. They are made of wood or metal, are hard to reuse, and require susbtantial resources to manage. Our plastic formworks are light and drastically lower risks and damages to the environment and other resources.

Just imagine if entire Manhattan is rebuilt with reusable plastic Formworks and with up to 20 % less concrete. The benefits on the environmental, economical, and human resources are drastic. Less woods are cut, less people injured, less transport used, less time used, less concrete used, and resulting buildings are safer.

My point is that concrete is a problem, and CNN Architecture did a great job to discuss it, but solutions is not a simple substitute. Our proposal is to improve the use of concrete by using less and actually improving building performance. This has been our goal for the past decades.