How high is the formwork? Which sizes are available?

The formwork is 75 cm high. The product range comprehends the following 10 sizes: 20,23,25,30,35,40,45,50,55,60 cm for 55 available configurations.

How much pressure does GEOTUB PANEL system resist to?

GEOTUB PANEL system resists up to 60 KN/m² fresh concrete pressure.

Are there any particular pour prescription? May I use any kind of concrete?

In accordance with the reference standards (UNI 11104: 2004, UNI EN 206: 2006 and DIN 18218: 2010-0) the casting speed is correlated to three macro factors:

- to the capacity of the formwork to withstand the thrust of fresh concrete;

- to the type of concrete used, e

- to the temperature of the environment in which the site operations take place.

Geotub Panel operates with a declared resistance limit of 60 kN / m2. This constraint, used as an entry in the pressure graph (available in the General Formwork Catalog) allows determining the maximum jet-speed allowed by the system

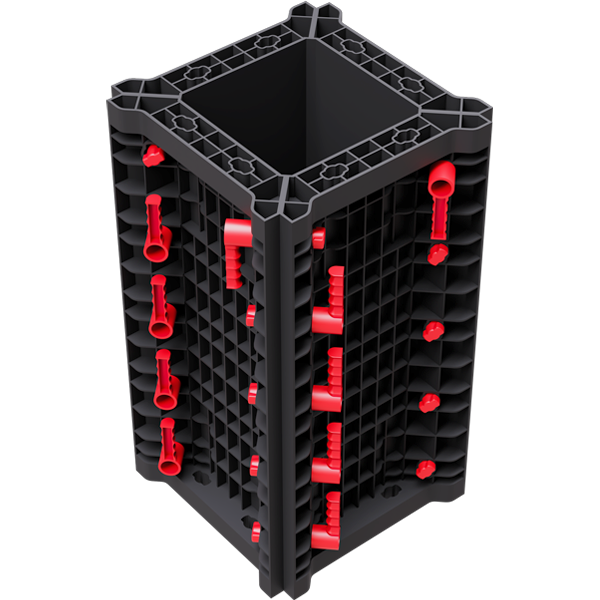

Are all the fixing handles necessary? How much traction do they resist?

Yes, they are. The supplied red handles resist up to 1200 Kg traction, but every one of them is necessary to guarantee the resistance of the formwork. The fixing of the panels can be only made with GEOPLAST handles, and any other method to join the GEOTUB PANELs can not be guaranteed by us.

Does the formwork require any dismantling agent?

No dismantling agent is required. It is necessary to properly clean the elements. If any dismantling agent is needed, use water-based ones or very diluted ones (2 parts water, 1 part dismantling agent).

How much time do I need to install the formwork for a column of 3,00 m high?

The first column requires 10-15 minutes. Then it is possible to move directly one half of the column, reducing a lot the installation time.

Until which height can I avoid the reinforcement bars?

Up to 40cm. Over this size, the panel must be reinforced with tie rods and anchor nuts. Such reinforcements are necessary to guarantee the resistance of the formwork and avoid the formation of breaks or deformations.

Which type of tie rods and anchor nuts do I need?

Traditional rolled bars are used (dywidag type Ø15 / 17 mm). Geoplast S.p.A. provides a universal nylon rosette with a steel core suitable to adhere perfectly to the formwork and designed for a correct distribution of the reaction following the thrust of the concrete. In any case, it is possible to use metal rosettes available on the market as long as they are compatible with the roll bar pitch and capable of guaranteeing a support surface and of the same diameter (Ø120mm) as the nylon washers in order to ensure the correct distribution of the effort normal on the structure of the quarterdeck.

Could other fixing systems be used to join the panels or to reinforce the structure?

The joining of the panels must be done with Geoplast nylon handles. Any other method to join the panels can not be guaranteed by the company. Any reinforcement system which could stiffen excessively the structure are to be avoided, as they could break the panels, which would not be ble to respond elastically to the pressure of fresh concrete. The panels must not be nailed. Bars F-UN2000 and UN 500-750-1000-1500 are proprietary by Geoplast and are not available in the market.

How high can I build with GEOTUB PANEL system?

The maximum casting height depends on the casting speed which is a function of the type of concrete, the temperature and the strength characteristics of the formwork.

Generally speaking, it can be asserted that in normal conditions a maximum jet height of 300 cm is easily reached.

It is possible to make columns of greater heights as long as the concrete thrown in the first phase has finished it’s setting and hardening phase, thus acquiring the mechanical characteristics necessary to sustain the action of the fresh concrete of the next phase.

How is GEOTUB PANEL system propped and plumbed?

The shoring is made through the stabilizer joint available in different sizes to match with the various types of props. Alternatively, for small columns, it is possible to fix the props under the ribs of the formwork.

How can GEOTUB PANEL be fixed to the ground?

The panels can be fixed to the ground through wooden reinforcements, fixing brackets or tie rods. This fixing method avoids the possible lifting of the panels.

How can the formwork be cleaned?

The formwork can easily be cleaned with water. A pressure washer can also be used in order to quicken the cleansing and obtain better results.