New Elevetor Data

Technical details

Load chart for NEW ELEVETOR H125:| LOAD TYPE | LOAD kg/m2 | Cope thickness cm | Weak concrete thickness cm | Gravel thickness cm | Ground pressure Kg/cm2 | Bars diameter mm | Mesh net cm x cm |

| CIVIL | 1.000 | 4 | 0 | 0 | 3,48 | 6 | 20 x 20 |

| 5 | 0 | 1,49 | |||||

| 10 | 0 | 0,82 | |||||

| 5 | 10 | 0,52 | |||||

| 1.800 | 5 | 0 | 0 | 5,74 | 6 | 20 x 20 | |

| 5 | 0 | 2,45 | |||||

| 10 | 0 | 1,36 | |||||

| 5 | 10 | 0,86 | |||||

| 5.000 | 7 | 10 | 15 | 0,65 | 8 | 20 x 20 | |

| INDUSTRIAL | 10.000 | 10 | 15 | 30 | 0,65 | 8 | 20 x 20 |

NEW ELEVETOR – Sizes and packagings

NEW ELEVETOR is available in a wide range of sizes (from 75 to 300cm).| Element | Actual size (cm) | Material | Package size (cm) | No. pieces per pallet |

| FORMWORK | 58 x 58 x H 15 | Polypropylene | 120 x 120 x 265 | 225 |

| QUATRO GRID | 58 x 58 x H 2.5 | Polypropylene | 110 x 110 x 250 | 352 |

| TRIO GRID | 60 x 40 | Polypropylene | 80 x 120 x 245 | 560 |

| PIPE | 75 > 300 x ø125 | PVC | ||

| LINTEL | 8 x 100 x H 10 | Polystyrene |

Installation

HOW TO INSTALL

Creation of a raised ventilated foundation, placed over columns with an upper slab made of concrete through the positioning of modular conected elements made of regenerated polypropylene over a preformed countertop. The elements have to be conected as NEW ELEVETOR system by Geoplast S.pA requires. This system is composed by a base grille with four arms 58×58, 2,5 high, PVC tubes with a variable height and 125 mm thick and square-base frameworks 58×58, 15 cm high lowered dome shaped, furnished with at least 4 countertops. They are used as a reference for the cast and for the correct positioning of the welded mesh in order to avoid the sinking of the framework support leg base. The reciprocally linked elements will recieve the cast of concrete with a strenght class of minimum 250 Rck. Then, they will set up a space with a square matrix in both ways. The created sanitary break will be used for systems passage or for the ventilation of the foundation.

- Prior preparation and compaction of the ground, create the laying surface made of concrete for NEW ELEVETOR SYSTEM with the required thickness.

- Laying of NEW ELEVETOR BASE (58 x 58 x h 2,5 cm), it is recommended to place the parts from right to left and from top to bottom.

- Fit tubes into each cup of the footing grid. The tubes are cut to the lenght suitable to achieve the specified heght of NEW ELEVETOR from 70 to 250 cm. In certain parts of the project the height can be lower than 70 cm, cutting the tubes at the desired heght.

- Place of the NEW ELEVETOR FORMWORK (58 x 58 x h15 cm): the operation is performed attaching the parts to the tubes from the right-hand side to the left, and from top to bottom, always keeping the printed arrow upwards.

- The Grid + Tube + Formwork assembly guarantees a perfect perpendicularity of the pillars within the foundation.

- Place, where necessary, a compensation listel made of polystyrene against the foundation beams.

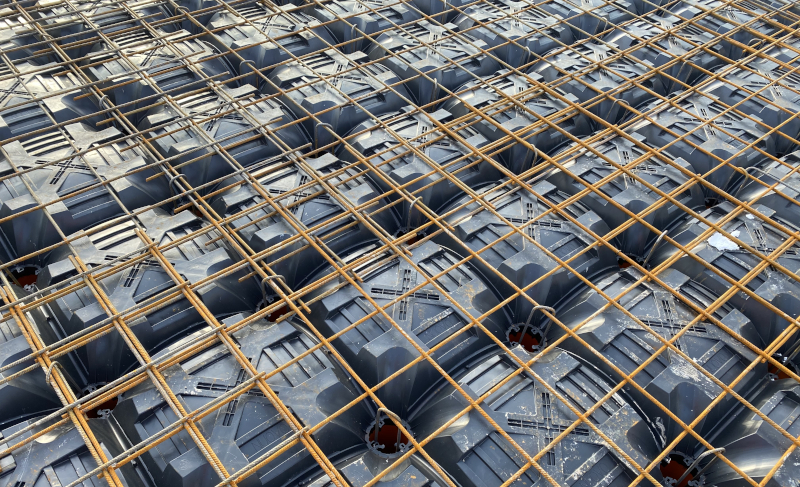

- Place the specified rebar mesh over the surface of the NEW ELEVETOR system (ref. to load table).

- Place of Ø 8 mm reinforcment bars within the tubes that are part of the NEW ELEVETOR system. These inserts must be joined to the reabar mesh used to reinforce the slab, and should be long enough to reach the base of the tube

- Slab pour: use a Rck 250 kg/cm2 concrete to fill the tubes and the fromwork, cover the reabar mesh and reach the designed slab thickness.

1. GRID

Installation of the base grid, essential for the pipes verticality and the structural resistance.

2. PIPES

Place the pipes of PVC in the base grids.

3. FORMWORK

Place New Elevetor from right to left and interlock in the pipes to guarantee a safe walkability.

4. COMPENSATION

In the starting sides, where the formwork leans against the wall, the listels of polystyrene avoid the concrete dispersion.

5. UPPER MESH

The upper mesh has to be placed right over the formwork or when required by the project over the spacers with an appropriate overlapping.

6. CONCRETE POUR

The pour comes after the end of the mesh installation. Pour concrete gradually from a side to the other and vibrate it properly

7. PIPES REINFORCEMENT

If required is recommended to reinforce every pipes of the system with appropriate reinforcing steel (following the Geoplast technical specifications).

8. CONCRETE POURING

The pour is performed after the end of the mesh installation. Pour concrete gradually from a side to the other and vibrate it properly.

9. FINISHED SLAB

Concrete slab is ready to use, built over and walkable.

TRIO GRID INSTALLATION

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

QUATRO GRID INSTALLATION

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

Comparison

Comparison between similar products

| FOUNDATION TYPE | NEW ELEVETOR SYSTEM | PREFABRICATED | WALLS AND FLOORING BLOCKS |

| MATERIAL | POLYPROPYLENE | CONCRETE | BRICK |

| Material impermeabilIty | WATER PROOF | POROUS | POROUS |

| Sizes (cm) | 58 x 58 | 60 x l | 61 x l |

| Ventilation Height (cm) | 70/250 | UNLIMITED | UNLIMITED |

| System Weight (kg/m2) | 3,3 + TUBE WEIGHT | N/A | 60 |

| Slab thickness (cm) | > 1 | 3/5 | Plank 5/6 – slab 5<>15 |

| Alowed Payloads (kg/m2) | UP TO 10000 | 500 | N/D |

| CLS Consumption (m3/m2) | 0,03 + TUBE CONSUMPTION | slab thickness function | slab thickness function |

| Place Speed (m2/ora) | ≈ 20 | N/D | 10 |

| Monolithic aspect of the System | YES | NO | NO |

| Assembly | MANUAL | MECHANICAL MEANS | MANUAL |

TECHNICAL AND ECONOMICAL ADVANTAGES

- MODULAR AND ADAPTABLE NEW ELEVETOR permits the realization of variable heights foundations and it can installed over surfaces without a weak concrete cover.

- INNOVATIVE NEW ELEVETOR is an innovative system sizes: 58X58 and 15 cm long. It can be used to realize a sanitary break with systems passage and reduction of concrete consumption and placement times.

- RESTRAINED CONSUMPTION Consumption are of 0,030 mc/mq to the edge, while the concrete quantity needed to fill the pilars is of 0,037 mc/mq per ml of height.

- EASY TO PLACE NEW ELEVETOR base is an element made of recycled polypropylene that guarantees a simple and fast place of the pvc tubes which sustain the elvetor system.

- PRECISION Precise system that mantains the tube perfectly vertical and of easy placement.

Notice

This website or its third party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. If you want to know more or withdraw your consent to all or some of the cookies, please refer to the cookie policy.

By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.