Skydome Data

Technical advantages

COST EFFECTIVE

The voids created with SKYDOME forms allow considerable savings in concrete compared to traditional full-concrete slabs. SKYDOME can be easily installed on H20 timber beams, thus saving any other scaffold system.

SAFETY

SKYDOME is completely independent, thus it does not require any support or safety structures. The system can be installed from below and it guarantees maximum safety to the workers.

TECHNOLOGY

The dome-shaped forms of SKYDOME allow to create large-spanning bi-directional waffle slabs guaranteeing maximum structural efficiency thanks to the lower self-weight of the structure.

DISMANTLING

Concrete does not stick to plastic, thus dismantling is extremely fast and easy without need of releasing agents. All elements can be cleaned just with water.

REUSE

Thanks to its shape and the material features, SKYDOME can be reused for more than 100 times.

HANDLING

The material is very light and can be dismantled and moved quickly on-site without using cranes. SKYDOME can be stored in tight spaces, even in damp ones.

RESULTS

A slab made with SKYDOME can be left exposed or covered with a plasterboard ceiling.

ECOLOGIC

SKYDOME system is completely made with recycled plastic materials.

Technical chart and Package

SKYDOME is made of ABS and it is resistant to UV and chemical agents

| ITEM | Ribbing width (cm) | Dome radius | Dome void | Ribbing axle spacing | Concrete consumption ribbing(m3/m2) | Concrete consumption slab (m3/m2) | ||||

| lower | middle | upper | 5 cm top slab | 10 cm top slab | 15 cm top slab | |||||

| L1 | L2 | L3 | ||||||||

| SKYDOME_H200 | 120 | 154 | 196 | 140 | 700 | 820 | 0.080 | 0.130 | 0.180 | 0.230 |

| 160 | 193 | 237 | 140 | 700 | 860 | 0.091 | 0.141 | 0.191 | 0.241 | |

| 200 | 233 | 279 | 140 | 700 | 900 | 0.100 | 0.150 | 0.200 | 0.250 | |

| SKYDOME_H250 | 120 | 170 | 213 | 140 | 700 | 820 | 0.099 | 0.149 | 0.199 | 0.249 |

| 160 | 210 | 254 | 140 | 700 | 860 | 0.113 | 0.163 | 0.213 | 0.263 | |

| 200 | 250 | 295 | 140 | 700 | 900 | 0.125 | 0.175 | 0.225 | 0.275 | |

| SKYDOME_H300 | 120 | 205 | 267 | 140 | 700 | 820 | 0.123 | 0.173 | 0.223 | 0.273 |

| 160 | 245 | 308 | 140 | 700 | 860 | 0.139 | 0.189 | 0.239 | 0.289 | |

| 200 | 285 | 350 | 140 | 700 | 900 | 0.153 | 0.203 | 0.253 | 0.303 | |

| SKYDOME_H350 | 120 | 263 | 302 | 140 | 700 | 820 | 0.151 | 0.201 | 0.231 | 0.301 |

| 160 | 303 | 342 | 140 | 700 | 860 | 0.169 | 0.219 | 0.269 | 0.319 | |

| 200 | 343 | 384 | 140 | 700 | 900 | 0.185 | 0.235 | 0.285 | 0.335 | |

| SKYDOME_H400 | 120 | 348 | 387 | 140 | 700 | 820 | 0.185 | 0.235 | 0.285 | 0.335 |

| 160 | 388 | 388 | 140 | 700 | 860 | 0.205 | 0.255 | 0.305 | 0.355 | |

| 200 | 428 | 430 | 140 | 700 | 900 | 0.222 | 0.272 | 0.322 | 0.372 | |

TABLE ELEMENTS per square meter:

| RIBBING (mm) | ON CENTRES (mm) | Nr. DOMES per m2 | TYPE OF BEAM | Nr. BEAMS per m2 | N° CUBES per m2 |

| 120 | 820 | 1.50 | SKYDOME T120 | 3.00 | 1.50 |

| 160 | 860 | 1.35 | SKYTOME T160 | 2.70 | 1.35 |

| 200 | 900 | 1.23 | SKYDOME T200 | 2.47 | 1.23 |

Installation

Installation

SKYDOME allows the reduction of the slab’s self-weight without using any disposable material, thus all components of the system can be reused and it allows an advanced dismantling.

Concrete does not stick to plastic, making dismantling quick and easy.

No releasing agents are required: all the elements of the system are easily cleaned just with water.

Installation Guide

1

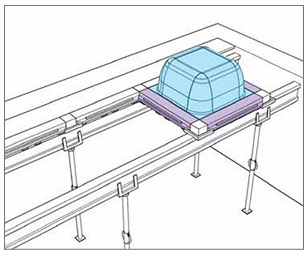

Place the steel props and insert the timber beams. Attach the item to the support wall.

2

Place the first row of cubes and beams.

3

Place the side panel of 25mm thickness.

4

Place the second row of elements at the same time of the transversal beams.

5

Place the first SKYDOME dome.

6

Repeat steps 4 and 5.

7

Place the first balance panel of 25 mm thickness.

INSTALLATION INSTRUCTIONS

In order to place correctly the balance panels on the side ribs, it is essential to consult GEOPLAST project tables before proceeding with the installation of the elements of the slab.

Dismantling SKYDOME system

1

Remove props and timber beams in pairs.

2

Remove the cubes.

3

Remove all the beams.

4

Remove SKYDOME domes with a bent iron bar that will be inserted into the holes on the side of the dome.

5

In correspondence of the ribs, shore up the slab as shown in GEOPLAST project tables until the concrete has cured.

Comparison

Comparison with similar systems

| Article | SKYDOME | BIG5 | BEEPLATE | PREDALLES |

| Material | ABS | PLASTIC | / | Expanded polystyrene |

| RESULT | TWO-WAY RIBBED SLAB | MONOLITHIC SLAB | MONOLITHIC SLAB | MONO-DIRECTIONAL SLAB |

| Size (cm) | 75 x 75 * | ø10 – ø45 | ø66 – ø70 | 40/50 x 100 |

| Height min – max (cm) | 20+4 – 40+4 * | 10 – 45 | 20 – 46 | 12 – 80 |

| Concrete consumption min-max (m3/m2) | 0,080 – 0,222** | 0,074 – 0,059 | 0,149 – 0,341 | 0,080 – 0,288 |

| Concrete savings (%) | 25% – 54% | 26% – 87% | 26% | 33% – 60% |

| SCAFFOLD | STANDARD | PRODUCT | PRODUCT | REQUIRED |

| STORAGE | STACKABLE | NON STACKABLE | N/A | NON STACKABLE |

| SLAB CONSUMPTION | 0,322 | 0,365 | 0,409 | 0,196 |

* dome element ** topping slab depth |

Notice

This website or its third party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. If you want to know more or withdraw your consent to all or some of the cookies, please refer to the cookie policy.

By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.