Skyrail Data

Technical advantages

REUSE

SKYRAIL is cost-competitive as it can be reused for at least 100 casts. The concrete doesn’t stick to the plastic so that the formwork can be cleaned with just some water, without using detergents or lubricants.

INSTALLATION AND DISMANTLING

Once the supporting system is built, position the ABS beam elements to create a stable support base for the domes. The SKYRAIL domes and SKYBLOCK closure accessories should be placed next. Once the installation is completed, the system will be dry walkable. The removal of the SKYRAIL system is possible 6-7 days after pouring the concrete and should be done in sequences: by removing the props, the yellow beams, and then the ABS beams. The operation should always start from the bottom.

MODULARITY

SKYRAIL is a modular element. It doesn’t need cuts od adaptations beacause only the neccessary elements for the cast are used.

STORAGE

SKYRAIL can be completely dismantled and it is not necessary to place it in dried places.

HANDLING ON-SITE

Thanks to its small size it can easily handled on-site and dismantled where needed.

RESULT

SKYRAIL surface can be left in sight without any further rework.

Technical characteristics and packagings

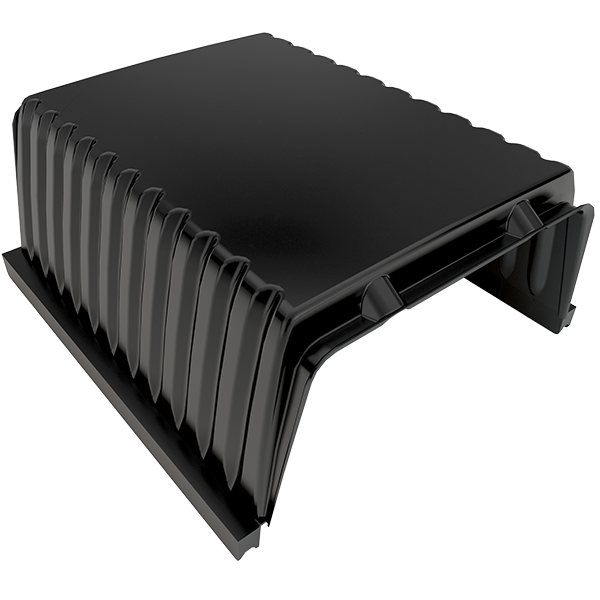

SKYRAIL is moulded in ABS resistant to UV rays and chemical agents.

| ITEM | AXLE SPACING (cm) | SPAN (cm) | SKYRAIL HEIGHT (cm) | BASE HEIGHT (cm) | TOTAL HEIGHT (cm) | RIBBING (cm) | CONCRETE CONSUMPTION UP TO THE TOP (m3/m2) | CONCRETE CONSUMPTION (m3/m2) | PROPS SPACING (m) |

| SKYRAIL_H16 | 60 | 51 | 16 | 4 | 20 | 9 | 0.033 | 0.073 | 3 |

| 60 | 51 | 16 | 5 | 21 | 9 | 0.033 | 0.083 | 3 | |

| SKYRAIL_H20 | 60 | 51 | 20 | 4 | 24 | 9 | 0.044 | 0.084 | 3 |

| 60 | 51 | 20 | 5 | 25 | 9 | 0.044 | 0.094 | 3 | |

| SKYRAIL_H24 | 60 | 51 | 24 | 4 | 28 | 9 | 0.054 | 0.094 | 3 |

| 60 | 51 | 24 | 5 | 29 | 9 | 0.054 | 0.104 | 3 |

| ITEM | PALLET SIZE (cm) | PALLET NR. ITEMS / KG | |

| SKYRAIL_H16 | 120 X 112 X 230 | 208 | 540 |

| SKYRAIL_H20 | 120 X 112 X 232 | 204 | 570 |

| SKYRAIL_H24 | 120 X 112 X 235 | 200 | 620 |

| SKYBLOCK_H16 | 80 X 120 X 230 | 288 | 337 |

| SKYBLOCK_H20 | 80 X 120 X 233 | 284 | 389 |

| SKYBLOCK_H24 | 80 X 120 X 235 | 280 | 440 |

| T JOIST | 80 X 120 X 220 | 140 | 258 |

Installation

SKYRAIL system installation

1

Place the iron props and the timber beams. Fix the supporting element to the wall.

2

Place the timber compensation panel or a GEOPANEL 80mm thick.

3

Place the 2 first rows of joists.

4

Place the timber compensation panel 25 mm thick.

5

Place the spacers between the joists.

6

Place the SKY BLOCK element.

7

Install the first SKYRAIL element.

8

Install SKYRAIL elements fixing them to each other.

ORDER OF INSTALLATION

In order to correctly place the compensation panels, it is necessary to consult GEOPLAST project tables before installing the slab elements.

SKYRAIL system dismantling

1

Remove the spacers.

2

Remove the props and the timber beams.

3

Remove the joists.

4

Remove SKYRAIL elements.

5

In correspondence of the ribs, shore up the floor as shown in GEOPLAST project tables until the complete curing of the concrete.

Comparison

Comparison between similar products

| CHARACTERISTICS | SKYRAIL SYSTEM | HOLLOW CLAY-CONCRETE |

| SAFETY | The system is fully self-supporting | It requires a bottom reinforcement and safety features |

| SAVINGS | The system is completely amortised after just a few pours | Waste materials are used |

| UTILIZATION | REUSABLE | JUST ONE USE(waste materials) |

| CONCRETE ADHESION | The lack of brick lightens the structure, improving the anti- seismic characteristics | The brick self-weight amplifies a seismic effect due to higher oscillating mass of the structure |

| INSTALLATION | Its low weight permits a fast and easy place | The weight and the fragility of the materials make the installation very slow |

| STORAGE | It can be stored in limited spaces and it does not suffer moisture | Needs a large storage area |

| INSTALLATIONS | The hydraulic systems can be easily installed | no previous arrangements needed |

Notice

This website or its third party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. If you want to know more or withdraw your consent to all or some of the cookies, please refer to the cookie policy.

By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.