New Elevetor Tank Data

Technical peculiarities

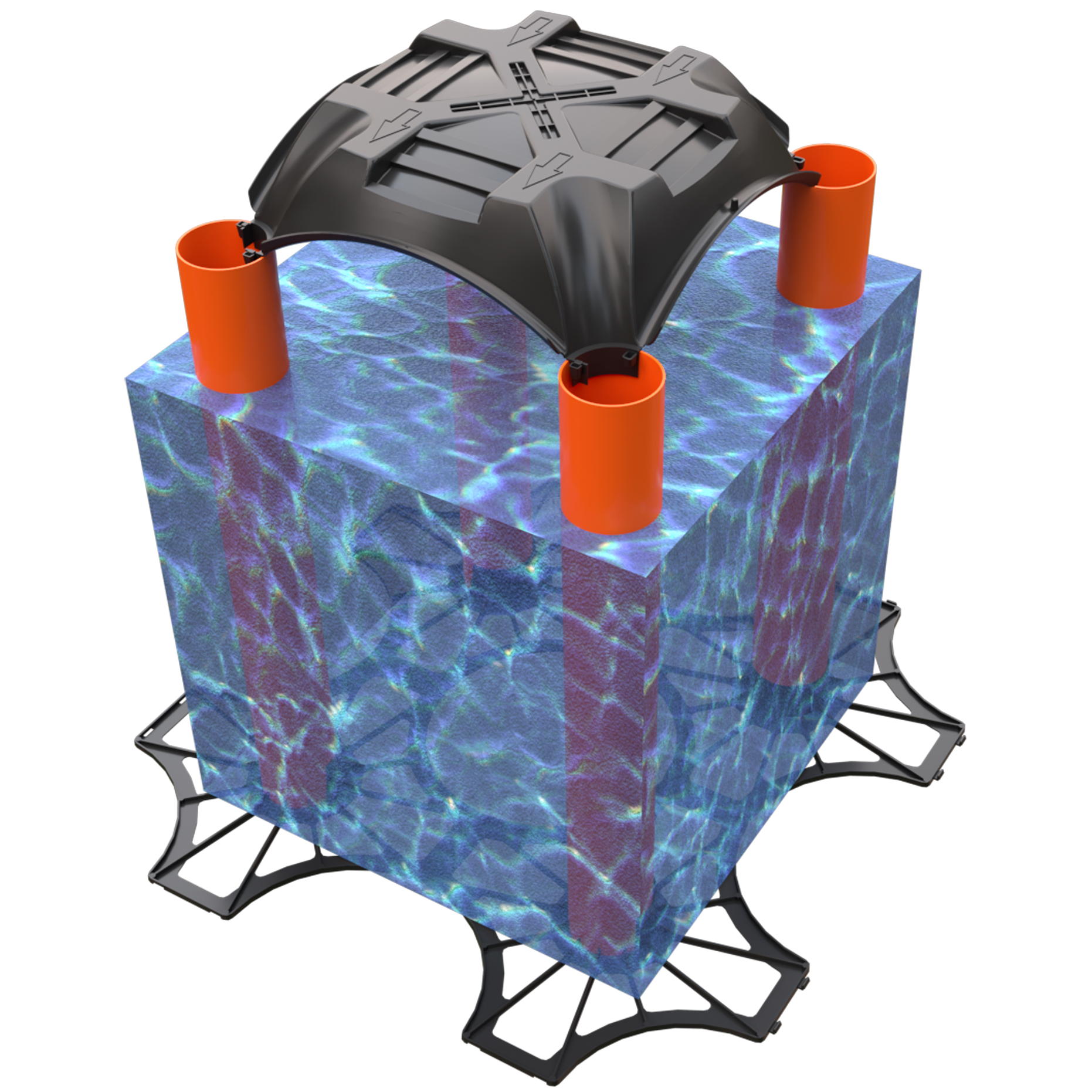

NEW ELEVETOR TANK system permits the creation of reinforced concrete tanks with a customizable height. It can be obtained by cutting the concrete tubes. The maximum nett internal height that can be reached is of 250 cm

| STORAGE CAPACITY | STORAGE CAPACITY | |||||

| *H |

m/m

|

l/m

|

*H |

m/m

|

l/m

|

|

| 80 |

0,564

|

564

|

170 |

1,464

|

1464

|

|

| 90 |

0,664

|

664

|

180 |

1,564

|

1564

|

|

| 100 |

0,764

|

764

|

190 |

1,664

|

1664

|

|

| 110 |

0,864

|

864

|

200 |

1,764

|

1764

|

|

| 120 |

0,964

|

964

|

210 |

1,864

|

1864

|

|

| 130 |

1,064

|

1064

|

220 |

1,964

|

1964

|

|

| 140 |

1,164

|

1164

|

230 |

2,064

|

2064

|

|

| 150 |

1,264

|

1264

|

240 |

2,164

|

2164

|

|

| 160 |

1,364

|

1364

|

250 |

2,264

|

2264

|

|

Installation

STRATIGRAPHY

The reinforced concrete structure that can be obtained with NEW ELEVETOR TANK consists of a slab, perimetral walls and a floor supported by pilars.This guarantees an high resitance to overloads, both continuous and live. The NEW ELEVETOR tank’s slab can be dig in in the case of the realization of a green area over the surface or it can be directly loaded for the vehicles transit.

In order to build a perfect tank, follow the stratigraphy below:

- Excavate up to the needed depth;

Place of a well compacted gravel bed;

Realization of the concrete perimetral walls RcK 300 Kg/cm² with metal reinforcements, with the thickness and the height required by the design. Then it is recommended to arrange the holes for the insertion of the water inlet and outlet pipes;

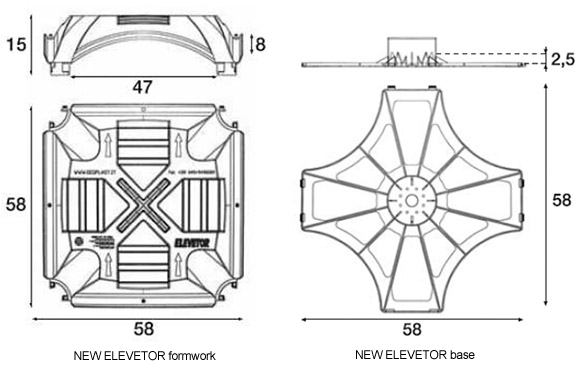

- Furnishing and place on-site of the NEW ELEVETOR TANK system chich consists of NEW ELEVETOR FORMWORKS modular and made of polypropylene, size 58X58, H15 cm,hooked to the tubes Ø 125 mm, variable height as required by the project. Comprehensive of NEW ELEVETOR BASE, placed on-site;

- Place of the welded mesh over the formworks extrados;

- Place of the metal reinforcements in the tubes. The reinforcements need to be hooked to the welded mesh of hood and touch the bottom of the tube;

- Cast of the hood with concreteRcK 300 Kg/cm² in order to fill the tubes and the formwork, thickness as required by the project. During this stage it is recommended to arrange possible holes for the inspection pits.

The tank can be directly overloaded on the hood or it can be filled in to create a parking lot or a green area over it.

NEW ELEVETOR BASE AND FORMWORK

New Elevetor base, regenerated element made of polypropylene, that guarantees an easy and fast place of the concrete tubes which sustain the NEW ELEVETOR system. It’s a very precise system thats mantains the tubes perfectly vertical and it is easy to place.

New Elevetor is an innovative system, sizes 58×58, height 15 cm, for the realization of a tank that permits the reduction of the concrete consumption and of the time of place. The consumption are of 0,030 m3/m2 at the edge, while the concrete quantity needed for the pilars’filling is of 0,037 m3/m2 per linear height meter.

Placing stages

STAGE 1

Preparation of the slab, the perimetral walls and arrangement of the inlet and outlet holes.

STAGE 2

Place of the NEW ELEVETOR BASE

STAGE 3

Place of the tubes

STAGE 4

Place of the NEW ELEVETOR FORMWORK

STAGE 5

NEW ELEVETOR system view

STAGE 6

Place of the welded mesh and of the reinforcement forks

STAGE 7

Pouring stage

Comparison

Comparison between similar products

|

||||||||||||||||||||||||||||||||||||

STRENGHTS, IT CAN BE INSPECTED

NEW ELEVETOR TANK can be inspected through an inspection pit.

The access to the tank interior permits:

- TIDINESS

- CHECK OF THE WATER LEVEL

- CHECK OF THE WATER MICROBIOLOGICAL STATUS

- CHECK OF ALL THE POSSIBLE PIPES OR INSTALLATIONS SITUATED IN THE TANK

ADVANTAGES IN RESPECT TO TRADITIONAL METHODS

- Accumulation and milwork tanks made of concrete and poured on-site

- The shape and the size of the basin are customizable

- Internal heights of the tank up to 2,5 m

- Dry walkability

- Fast and easy placing

- Can be inspected

- Light

- Elevation means not needed

Notice

This website or its third party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. If you want to know more or withdraw your consent to all or some of the cookies, please refer to the cookie policy.

By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.