AIRPLAST has lower feet (15 mm) which allow a perfect locking between the element and the concrete slab, thus avoiding any later movement.

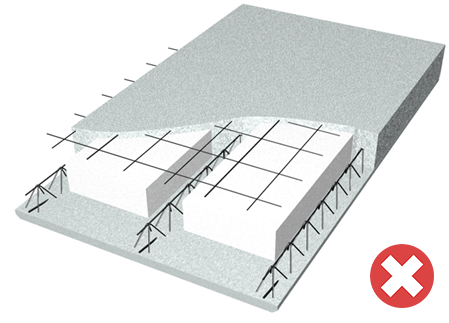

Polystyrene is laid directly on fresh concrete and the only adherence between the element and the slab is the superior slab. The result is a not completely stable surface.

AIRPLAST formwork is made of polypropilene and is therefore very resistant and does not fear any breakage during the construction operations.

Polystyrene is a very light yet brittle material which can be easily brocken. Moreover its leavings often befoul the construction site and slow down the operations.

An AIRPLAST formwork is impermeable and does not hold water: therefore they don’t release water over time with formation of moisture stains.

Polystyrene is a porous material which hold water, thus releasing moisture over time, with formation of stains.

Thanks to the impervious characteristic of the formwork, there is no risk of water release over time and therefore the slab finish will be always excellent.

Water hold by polystyrene can be harmful for the slab: as a matter of fact, it produces moisture which cause stains and mold.

AIRPLAST does not contain any harmful or exploding gas, thus it does not require a ventilation system in order to obtain a REI slab.

To obtain a REI slab it is necessary to have a ventilation system in the intrados to let styrene (an harmful gas) get out in case of fire.

SIMPLIFIED INSTALLATION

EASILY STORABLE

HIGH LOAD-BEARING CAPACITY

NO IMBIBITION

CLEAN CONSTRUCTION SITE

NO WATER RELEASE OVER TIME

NO VENTILATION SYSTEM REQUIRED

LONG-LASTING FINISH

SOMETIMES DIFFICULT INSTALLATION

STORABLE IN SHELTERED PLACES

EASILY BREAKABLE OF POLYSTYRENE

IMBIBITION PROBLEMS

“DIRTY” CONSTRUCTION SITE

WATER RELEASE OVER TIME

VENTILATION SYSTEM REQUIRED

NO GUARANTEE OF LONG-LASTING FINISH

Notice

This website or its third party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. If you want to know more or withdraw your consent to all or some of the cookies, please refer to the cookie policy.

By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.